The process equipment market has been highly active in recent years, with notable key mergers and acquisitions observed in the top market share holders.

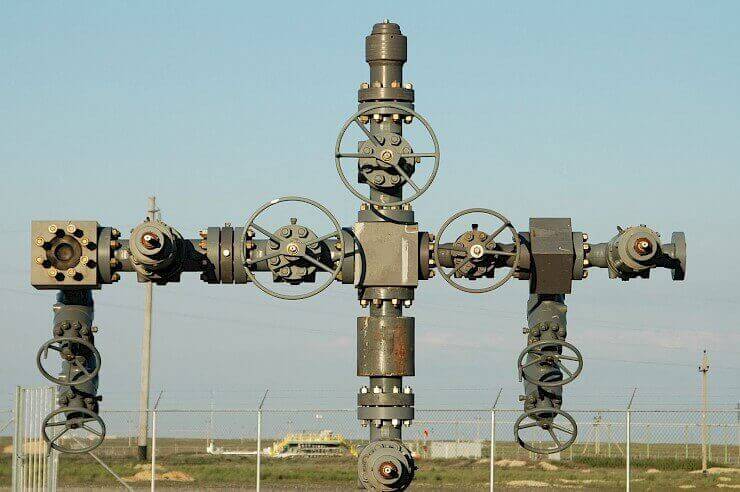

The valve and actuator market is expected to reach revenues around £5.1 billion by the end of 2020 as a direct result of prominent expansion observed in key industries such as extraction and production of oil and gas and water management.

The expansion in the oil and gas production has also influenced the growth of other energy dependent industries, such as power generation and chemical manufacturing, which has led to higher demand for flow control equipment market across North America.